the

Heavy Duty Bolt

We developed our Heavy Duty Bolt to deal with a specific set of circumstances.

On occasion, the shear plane of the elements being fixed would fall across the legs of a standard Blind Bolt. To remedy this, we developed a shorter, heavy duty blind fixing capable of delivering improved performance under these circumstances

The Heavy Duty Blind Bolt is the ideal fixing solution for joining heavier steel sections to each other. It has been designed, using an innovative locking pin and an expanding base, so that it can be utilised using simply a spanner and a hammer. The lack of any requirement for specialised tools means that our Heavy Duty Blind Bolts save designers and builders both time and money.

- Locking pin mechanism facilitates quick and easy installation

- Holes don’t need to be any larger than usual

- Protection from 600 hours exposure to salt spray provided by a Dacralon coating

- Simplified application speeds construction and saves money

If you want to stay on top of all of our exciting new products and developments, please visit our news page, or contact us using the details below. Tell us about your next project, and we’ll explain how we could help.

HEAVY DUTY BOLT

Technical Details

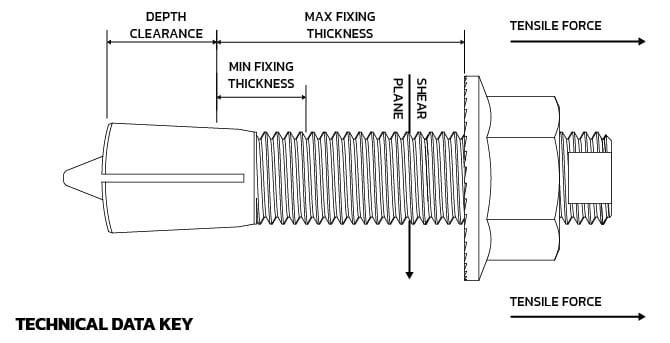

NOTE: All dimensions are in mm unless stated otherwise.

The Blind Bolt Company reserve the right to change these technical details without notice.

Heavy Duty Product Specification Zinc Flake 1000Hr SSP

|

||||||

| Product Code |

Bolt Size |

Hole Diameter | Fixing Thickness | Depth Clearance |

Corrosion Protection |

|

| Min | Max | |||||

| HD0845ZF | M8 x 45 | 8 | 7 | 25 | 10 | Zinc Flake 1000Hr |

| HD1045ZF | M10 x 45 | 10 | 7 | 25 | 12 | Zinc Flake 1000Hr |

| HD1060ZF | M10 x 60 | 10 | 7 | 40 | 12 | Zinc Flake 1000Hr |

| HD1245ZF | M12 x 45 | 12 | 8 | 22 | 15 | Zinc Flake 1000Hr |

| HD1260ZF | M12 x 60 | 12 | 8 | 34 | 15 | Zinc Flake 1000Hr |

| HD1275ZF | M12 x 75 | 12 | 8 | 48 | 15 | Zinc Flake 1000Hr |

| HD1660ZF | M16 x 60 | 16 | 12 | 30 | 25 | Zinc Flake 1000Hr |

| HD1675ZF | M16 x 75 | 16 | 12 | 45 | 25 | Zinc Flake 1000Hr |

| HD2070ZF | M20 x 70 | 20 | 15 | 32 | 30 | Zinc Flake 1000Hr |

| HD2085ZF | M20 x 85 | 20 | 15 | 47 | 30 | Zinc Flake 1000Hr |

Design Resistance for HD Type Blind Bolts Design to BS EN 1993-1-8

|

|||

| Bolt Size | Tensile (kN) | Single Shear (kN) | Recommended Pre-load Tightening Torque (Nm) |

| M8 |

8.5 |

13.6 | 20 |

| M10 | 25.2 | 21.9 | 35 |

| M12 | 46.4 | 32.2 | 45 |

| M16 | 57.5 | 60.8 | 95 |

| M20 | 77.5 | 95.5 | 120 |

Important Note

The above resistances are equally appropriate for designs to BS 5950

Stainless Steel HD Bolts

Heavy Duty Product Specification A4-70 STAINLESS STEEL |

|||||

| Product Code |

Bolt Size |

Hole Diameter | Fixing Thickness | Depth Clearance | |

| Min | Max | ||||

| HD0845SS | M8 x 45 | 8 | 7 | 25 | 10 |

| HD1045SS | M10 x 45 | 10 | 7 | 25 | 12 |

| HD1060SS | M10 x 60 | 10 | 7 | 40 | 12 |

| HD1245SS | M12 x 45 | 12 | 8 | 22 | 15 |

| HD1260SS | M12 x 60 | 12 | 8 | 37 | 15 |

| HD1660SS | M16 x 60 | 16 | 12 | 30 | 25 |

| HD2070SS | M20 x 70 | 20 | 15 | 32 | 30 |

Design Resistance for HD Type Blind Bolts

|

|||

| Bolt Size | Tensile (kN) | Shear (kN) | Recommended Pre-load Tightening Torque (Nm) |

| M8 |

10.5 |

11.5 | 18 |

| M10 | 20.2 | 18.4 | 24 |

| M12 | 31.4 | 27.1 | 30 |

| M16 | 40.1 | 51.1 | 45 |

| M20 | 68.7 | 80.2 | 80 |

Important Note

The above resistances are equally appropriate for designs to BS 5950

HEAVY DUTY BOLT

Testing Terms Explained

The Heavy Duty bolt was developed with a specific need in mind. Sometimes the shear plane in question would fall across the legs of a Standard Blind Bolt, and so we developed a shorter blind fixing able to offer improved performance when used in this scenario.

The Heavy Duty Blind Bolt offers the perfect blind fixing solution when heavier steel sections have to be joined together. The design, which incorporates an expanding base and an innovative locking pin, means that the only tools which have to be used are a hammer and a spanner. The fact that blind bolt fasteners don’t call for specialised tools is just one of the reasons why they save builders and designers so much time and money.

- Unique locking pin enables quick and easy installation

- No need to drill larger holes than normal

- Dacralon coating provides protection from 600 hours exposure to salt spray

- Ease of use means construction takes place more quickly and costs less

If you want to stay on top of all of our exciting new products and developments, please visit our news page, or contact us using the details below. Outline your project to us, and we’ll explain how blind bolt fasteners could make a difference.

HEAVY DUTY BOLT

Fitting Instructions

The following videos visually represents the detailed installation of the Heavy Duty Bolt.

HD Bolt Installation Instruction