solution

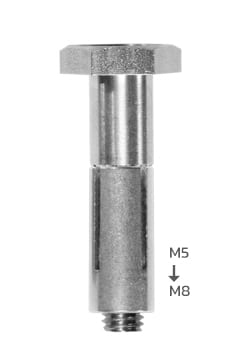

find the right Blind Bolt

The smart

solution

for steelwork connections

Find

your

Standard

Blindbolt

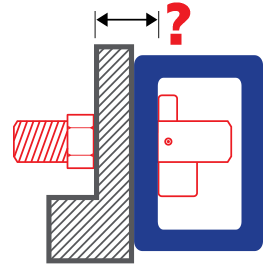

Input The Total Thickness

(Total Clamping Thickness)

Save time,

Save money,

Fix it with a Blind Bolt

How does it work?

Contact

Got a question?

Get in touch by using our contact for, sending an email, or calling us on:

+603-33775597